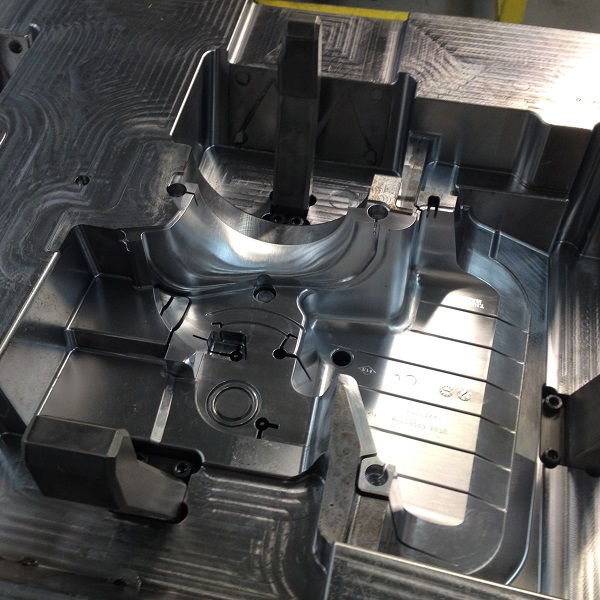

From concept to precision reality

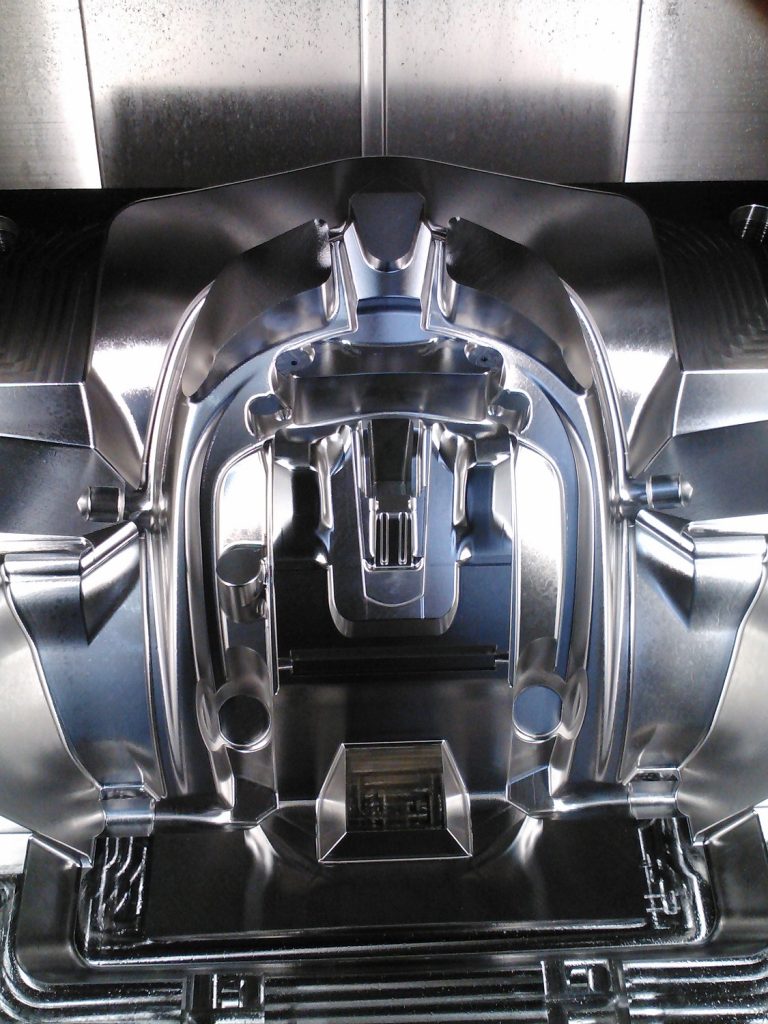

At ISO Meccanica, the design phase is the core of our production process. Thanks to advanced CAD/CAM software, our team transforms every idea into a precise digital model, ready for machining. This allows us to:

- Optimize machining parameters (cutting paths, feed rates, spindle speeds) already during the design phase, reducing setup times and minimizing errors.

- Simulate each component using digital twin technologies to detect potential issues or collisions before reaching the shop floor.

- Customize every project, adapting to complex geometries and customer-specific needs while ensuring the highest levels of accuracy and quality.

Innovation and reliability

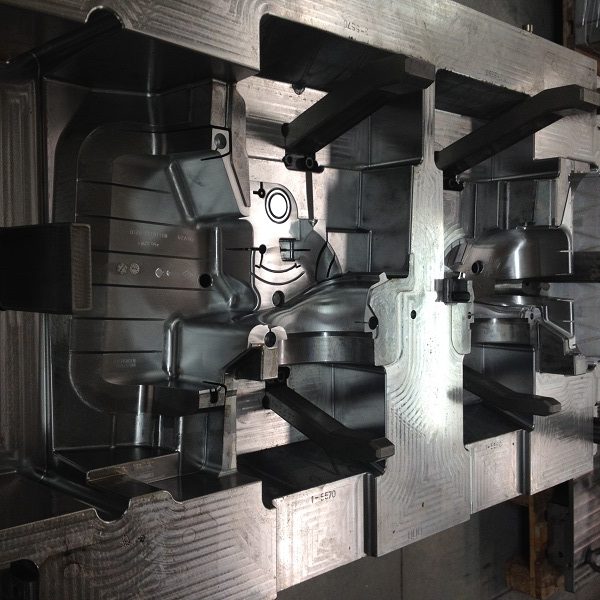

We adopt top-tier tools to:

- Identify and resolve issues directly in the digital model.

- Improve overall efficiency and extend tool life.

- Guarantee consistent and repeatable results—whether for prototypes or large production runs.

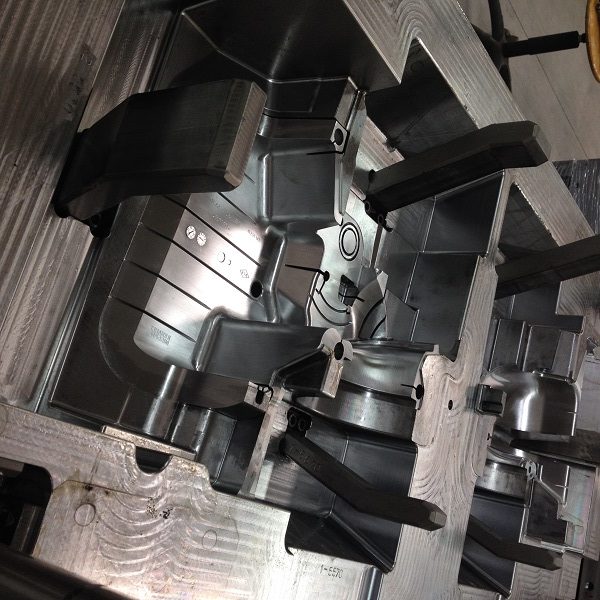

Tailored development and collaboration

Our design approach is highly collaborative:

- Needs analysis – We meet with the customer to define objectives, technical constraints, and expectations.

- CAD development – We create a 3D model including dimensions, tolerances, and material specifications.

- Review and optimization – We share design drafts for feedback, ensuring technical feasibility and refinements.

- Transition to production – We transfer the finalized project to the machining department, maintaining full continuity.